Laser Ablation - Amber Cai, Caleb Eades, Hao Cao & Marc Finzi

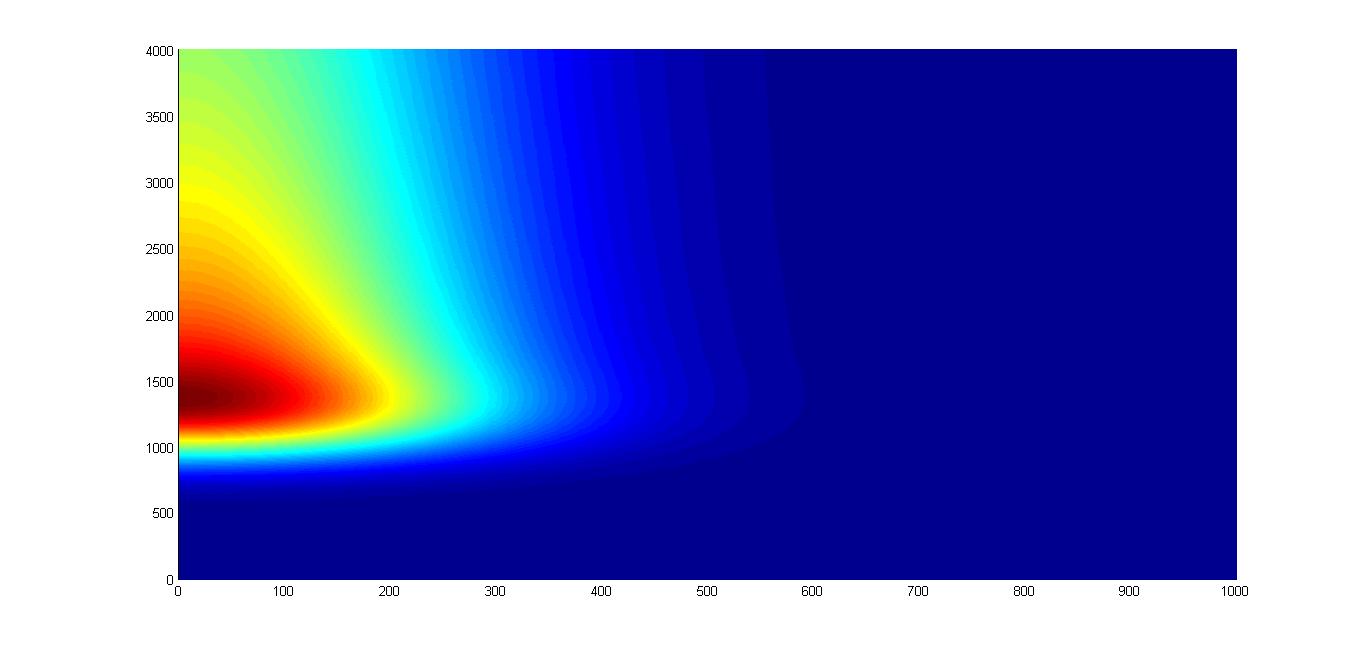

Figure 1: A contour plot showing the thickness of the silicon as a function of radial distance from the center of the ablation beam and time. Time is the vertical axis while the radial distance is the horizontal axis. 1000 corresponds to 10 nanoseconds for the time axis, and 1000 corresponds to 50 micrometers for the radial distance axis. The silicon starts at 500 micrometers thick, which is the blue areas, while the darkest red section is about 500.6 micrometers thick.

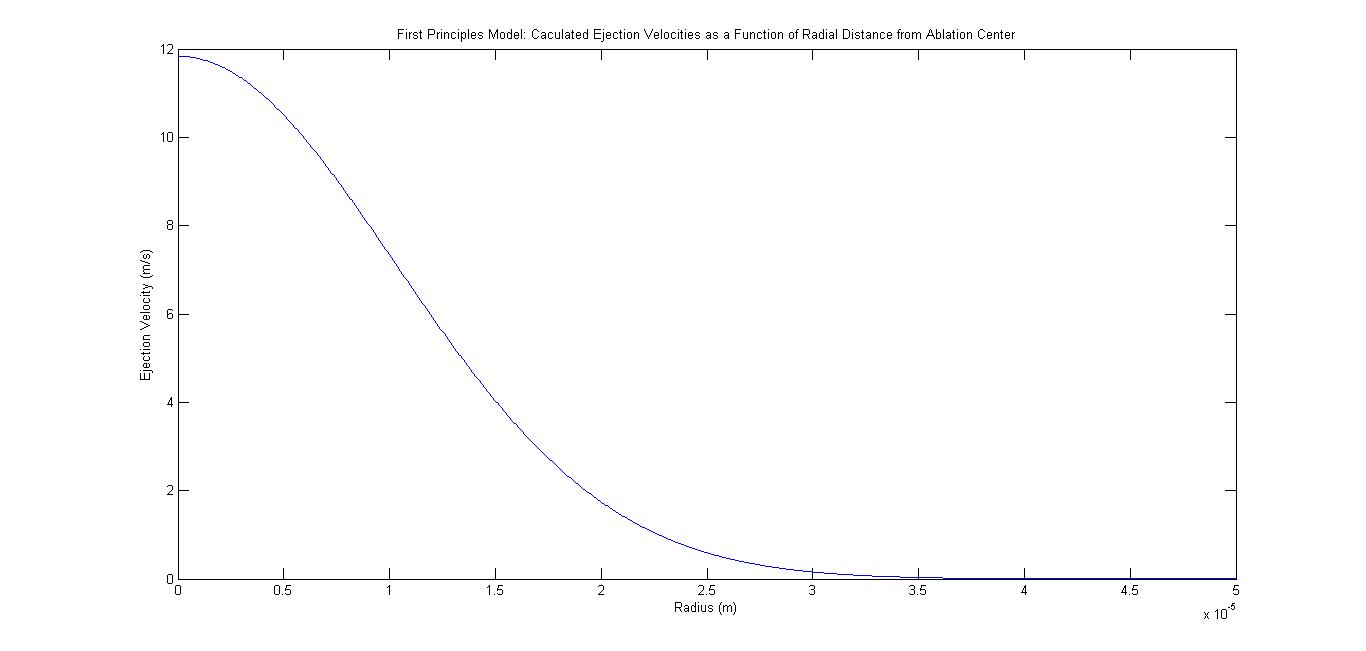

Figure 2: The corresponding velocity distribution function resulting from the surface expansion whose contour plot is shown in Figure 1. Here, the ejection velocity is plotted as a function of the radial distance from the center of the ablation beam.

Overview

Our goal is to deliver wavelength-scale plasma targets to the focus of a high-intensity laser in order to investigate stochastic heating as a possible source of hot electrons from a spherical plasma.

Current Progress

Our wavelength-scale plasma targets are spherical polystyrene nanospheres. These must reach the focus of the high-intensity laser without support structures, meaning as individual spheres that are neither touching other spheres nor any other material. Our method for doing this is a two-step method.

First, we deposit the polystyrene nanospheres on a silicon wafer to ideally obtain a hexagonal-close-packing structure in a monolayer. We then use a single pulse of an ablation laser to "ablate" these spheres off of the surface. After ablation, the spheres plume outwards and we attempt to hit one with the high-intensity laser coming in perpendicularly to the propagation path of the ablation laser.

At the moment, our spheres are sticking together after ablation due to inter-sphere bonds formed during the deposition process. We are investigating solutions to this problem. Recently, it appears that etching these spheres with an oxygen plasma in low pressure is dissolving the bonds between the spheres. It also reduces the sphere size because the plasma unilaterally eats away at every polystyrene surface it encounters.

If this plasma etching does turn out to eliminate the bonds between the spheres, then we will proceed with particle collection and time-of-flight analysis. In collection, we are going to ablate the spheres as usual but then have aluminum foil where the focus of the high-intensity laser would have been. This will tell us the angular distribution of the spheres in their flight. With the time-of-flight analysis, we will determine the optimal time to fire the high-intensity laser relative to the ablation laser in order to have the highest probability of hitting a single sphere in isolation.

(NOTE: Clicking any of these links will go to an embedded PDF screen. To get back to this page, simply click the back button on your browser.)

If you would like to see the slides from a presentation that Caleb gave recently for his senior fall 2015 thesis talk,

click here.

To view the Safety Operating Procedures (SOP) for plasma etching,

click here.