Depositions - Amber Cai, Caleb Eades, Hao Cao & Marc Finzi

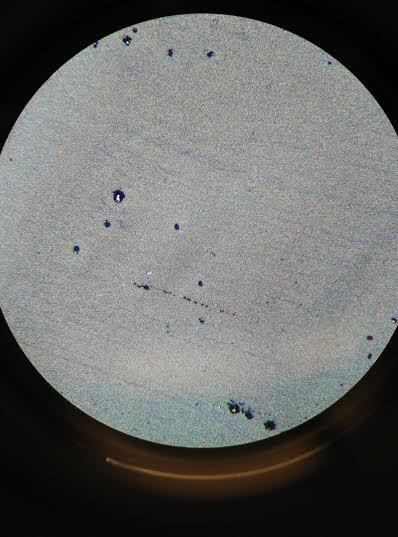

Figure 1: Image of a deposition of polystyrene spheres on a silicon substrate. This is taken through the eyepiece of an optical microscope.

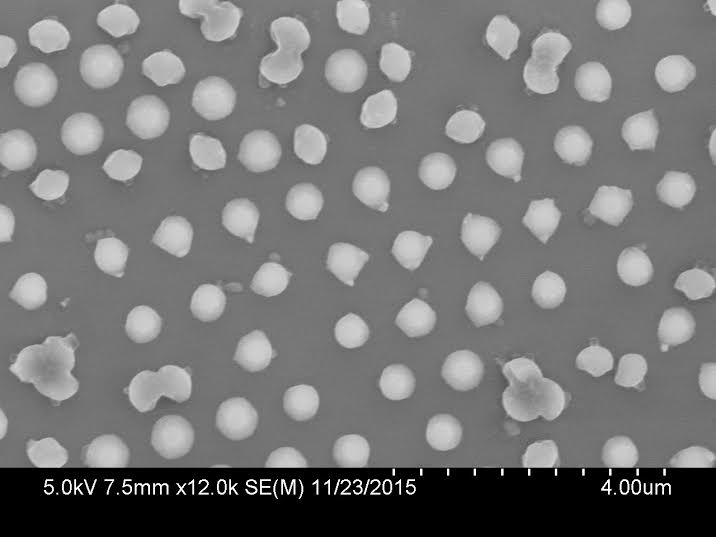

Figure 2: SEM image of on of our samples. Notice that the spheres are not bonded to each other and are isolated on the silicon substrate.

Overview

By depositions, we really mean sample preparation in general. The idea is to get a uniform monolayer of spheres bonded to a silicon substrate with no interstitial bonds between the spheres.

Current Progress

Amber: "My job over the summer was to develop a new method of depositing polystyrene nanospheres uniformly onto silicon substrates, effectively driven by the capillary force of various liquids. I made a lot of progress, but the project was basically abandoned halfway because the priority of the group (I guess until we graduate) became breaking the bonds. This semester we built and optimized the plasma etcher which is now capable of breaking the bonds between polystyrene spheres, so the next step is to find the optimal etching conditions for all sphere sizes. On the other hand I deposited, ejected and collected silica spheres as a back-up plan. SEM image shows that the silica spheres exhibit some tendency of sticking, although there is no bond physically visible. The sticking is most likely due to Van der Waals force. Therefore the next thing to do with silica spheres is to plasma-etch them in order to clean the organics, and apply a method called critical drying suggested by Professor Gerbode, which might form a monolayer of silica spheres without bonding."